أنشئ حسابًا أو سجّل الدخول للانضمام إلى مجتمعك المهني.

Thank you for invitation>>>

The advantage and disadvantage for box girder :

The continuing expansion of highway network throughout the world is largely the result of great increase in traffic, population and extensive growth of metropolitan urban areas. This expansion has lead to many changes in the use and development of various kinds of bridges. The bridge type is related to providing maximum efficiency of use of material and construction technique, for particular span, and applications. As Span increases, dead load is an important increasing factor. To reduce the dead load, unnecessary material, which is not utilized to its full capacity, is removed out of section, this results in the shape of box girder or cellular structures, depending upon whether the shear deformations can be neglected or not. Span range is more for box bridge girder as compare to T-beam Girder Bridge resulting in comparatively lesser number of piers for the same valley width and hence results in economy.

A box girder is formed when two web plates are joined by a common flange at both the top and the bottom. The closed cell which is formed has a much greater torsional stiffness and strength than an open section and it is this feature which is the usual reason for choosing a box girder configuration.

Box girders are rarely used in buildings (box columns are sometimes used but these are axially loaded rather than in loaded in bending). They may be used in special circumstances, such as when loads are carried eccentrically to the beam axis

“When tension flanges of longitudinal girders are connected together, the resulting structure is called a box girder bridge”.

Box girders can be universally applied from the point of view of load carrying, to their indifference as to whether the bending moments are positive or negative and to their torsional stiffness; from the point of view of economy.

Historical development and description of box girder:

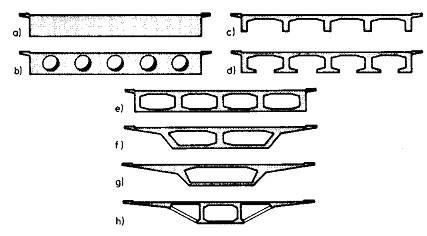

The first box girder cross section possessed deck slabs that cantilevered out only slightly from the box portion shown in figs a to e. With the prestressed concrete the length of cantilever could be increased. The high form work costs caused a reduction in the number of cells fig (f, g, h). In order to reduce the construction loads to minimum possible extent or to require only one longitudinal girder in working states even with multiple traffic lanes.

It was only with the development of high strength prestressing steel that it became possible to span longer distances. The first prestressed concretebridges, most of I-cross sections were built towards the end of the1920’s.The great breakthrough was achieved only after1945. “THE SCLAYN” bridge over the river Maas, which was built by Magnel in1948, was the first continuous prestressed concrete box-girder bridge with2 spans of62.70m. In following years the ratio of wages to material costs climbed sharply. This thereby shifted the emphasis of development of construction method. The box girder cross-section evolved structurally from the hollow cell-deck bridge or T-beam Bridge. The widening of the compression zone that began as a structural requirement at the central piers was in the extended throughout the entire length of bridge because of advantages transverse load-carrying characteristics.

Evolution of Box Girder:

The spanning of bridges started with simple slabs. As the spans increased, the design depth of slab is also increased. It is known that material near centre of gravity contributes very little for flexure and hence can be removed. This leads to beam and slab systems. The reinforcement in bottom bulb of beam provided capacity for tensile forces and top slab concrete, the capacity to resist the compression. They formed a couple to resist flexure.

As the width of slab is increased more number of longitudinal girders are required resulting in reduction of stiffness of beams in transverse direction and relatively high transverse curvature. The webs of beams get opened out spreading radially from top slab. Under high transverse bending these will no longer be in their original position. To keep it in their original position the bulbs at bottom should be tied together which in-turn leads to evolution of box girder. Long spans with wider decks and eccentric loading on cross-section will suffer in curvature in longitudinal and transverse direction causing heavy distortion of cross-section. Hence the bridges should have high torsional rigidity in order to resist the distortion of cross-section deck to a minimum.

Accordingly box girders are more suitable for larger spans and wider decks, box girders are to be suitable cross-section. They are elegant and slender. Economy and aesthetics further lead to evolution of cantilevers in top flanges and inclined webs in external cells of box girder. The dimension of cell could be controlled by prestressing.

As the span and width increases the beams and bottom slabs are to be tied to keep the geometry which in turn leads to evolution box girder.

Any eccentric load will cause high torsional stresses which will be counter acted by the box section. The analysis of such sections are more complicated due combination of flexure, shear, torsion, distortion. But it is more efficient cross-section. It is used for larger spans with wide cross-section. It can be used for spans up to150m depending upon the construction methods. Cantilever method of construction is preferred most.

Advantages Associated with Box Girders:

Disadvantages:

One of the main disadvantages of box decks is that they are difficult to cast in-situ due to the inaccessibility of the bottom slab and the need to extract the internal shutter. Either the box has to be designed so that the entire cross section may be cast in one continuous pour, or the cross section has to be cast in stages.

It can cover a range of spans from25 m up to the largest non-suspended concrete decks built; of the order of300 m. Single box girders may also carry decks up to30 m wide. For the longer span beams, beyond about50 m, they are practically the only feasible deck section. Below30m precast beams or voided slab decks are more suitable while above50ma single cell box arrangement is usually more economic.

Single cell box-girder cast-in-situ are used for spans form40m to270m.The box arrangement is done in order to give aesthetic appearance where the web of box will act as a slender appearance when combined with a slim parapet profile. Single box arrangements are efficient for both the longitudinal and transverse designs, and they produce an economic solution for mot medium and long span structures. This type of deck is constructed span-by-span, using full-height scaffolding or trusses, or as balanced cantilever using form travelers. This could be particularly important for medium length bridges with spans between40m and55m. Such spans are too long for twin rib type decks, and too short for cast-in-situ balanced cantilever construction of box girders, while a total length of box section deck of less than about1,000 m does not justify setting up a precast segmental facility.

Haunches:

The uprights have to carry the same bending moment as the haunch, but with the benefit of a compression force due to the weight of the roof. Thus they may be slightly thinner than the haunches. Haunches are always economical. They provide the twin benefits of attracting moment away from mid-span and then providing a greater lever arm to resist this moment economically. Even very short haunches are valuable in reducing the hogging reinforcement.

About the T-Beam :

A T-beam, used in construction, is a load-bearing structure of reinforced concrete, wood or metal, with a t-shaped cross section. The top of the t-shaped cross section serves as a flange or compression member in resisting compressive stresses. The web of the beam below the compression flange serves to resist shear stress and to provide greater separation for the coupled forces of bending.[1]

The T-beam has a big disadvantage compared to an I-beam because it has no bottom flange with which to deal with tensile forces. One way to make a T-beam more efficient structurally is to use an inverted T-beam with a floor slab or bridge deck joining the tops of the beams. Done properly, the slab acts as the compression flange.

Overview and History of T-Beams[edit]A T-beam is a structural element able to withstand large loads by resistance in the beam or by internal reinforcements. In some respects, the T-beam dates back to the first time a human formed a bridge with a pier and a deck. After all, a T-beam is, in one sense, no more than a pillar with a horizontal bed on top, or, in the case of the inverted T-beam, on the bottom (Ambrose & Tripeny,2007, p.104). The upright portion carrying the tension of the beam is termed a web, and the horizontal part that carries the compression is termed a flange (See Figure1. below). However, the materials used have changed over the years but the basic structure is the same. T-beams structures such as highway overpasses, buildings and parking garages, have extra material added on the underside where the web joins the flange to reduce the T-beam’s vulnerability to shear stress (Chajas,1995, p.295). However, when one investigates more deeply into the design of T-beams, some distinctions appear.

The T-beam, though simple in design, contains multiple design elements of interest. Unlike an I-beam, a T-beam lacks a bottom flange, which carries savings in terms of materials, but at the loss of resistance to tensile forces (Mirza & Furlong,1985, p.112). Parking garages, however, it is obvious that this lack of a bottom flange on a T-beam actually serves as an advantage in that the stem rests on shelf making the flange the upper deck (See Figure2. below). T- beam designs come in many sizes, lengths and widths depending on what the structure is and its compression tension needs. However, the simplicity of the T-beam is in question by some who would rightly test more than one complex structure; for example, Cheng, Mohammed, and Mustapha (2009 and Hashim Fidow2014 tested pretension inverted T-beams with circular web openings (p.203), with mixed but generally favorable results. Thus, in some cases, the extra time and effort invested in creating a more complex structure proves worthwhile. A simpler matter to consider is that of which material or materials make up the construction of T-beams.

Steel T-beams manufacturing process includes: hot rolling, extrusion, plate welding and pressure fitting. A process of large rollers connecting two steel plates by pinching them together called pressure fitting is a common process for non-load bearing beams. The reality is that for most roadways and bridges today, it is more practical to bring concrete into the design as well. As pointed out by McCormac and Brown (2007), most T-beam construction is not with steel or concrete alone, but rather with the composite of the two, namely, reinforced concrete. Though the term could refer to any one of a number of means of reinforcement, generally, the definition is limited to concrete poured around rebar. MacGregor et al. (1997) describe this material and its use in T-beams at length, concluding that it is invaluable for the types of structures found in modern architecture. This shows that in considering materials available for a task, engineers need to consider the possibility that no one single material is adequate for the job; rather, combining multiple materials together may be the best solution. Thus, steel and concrete together can prove ideal.

Concrete alone is brittle and thus overly subject to the shear stresses a T-beam faces where the web and flange meet. This is the reason that steel is combined with concrete in T-beams. Lim, Paramasivam, and Lee (1987) discuss the problem of shear stress leading to failures of flanges detaching from webs when under load. This could prove catastrophic if allowed to occur in real life; hence, the very real need to mitigate that possibility with reinforcement for concrete T-beams. In such composite structures, many questions arise as to the particulars of the design, including what the ideal distribution of concrete and steel might be: “To evaluate an objective function, a ratio of steel to concrete costs is necessary” (Chou,1977, p.1605). This demonstrates that for all aspects of the design of composite T-beams, equations are made only if one has adequate information. Still, there are aspects of design that some may not even have considered, such as the possibility of using external fabric-based reinforcement, as described by Chajes et al. (1995), who say of their tested beams, “All the beams failed in shear and those with composite reinforcement displayed excellent bond characteristics. For the beams with external reinforcement, increases in ultimate strength of60 to150 percent were achieved” (p.295). When it comes to resistance to shear forces, external reinforcement is a valid option to consider. Thus, overall, the multiple important aspects of T-beam design impress themselves upon the student of engineering.

An issue with the T-beam compared to the I-beam is the lack of the bottom flange. In addition, this makes the beam not as versatile because of the weaker side not having the flange making it have less tensile strength.

Concrete beams are often poured integrally with the slab, forming a much stronger “T” – shaped beam. These beams are very efficient because the slab portion carries the compressive loads and the reinforcing bars placed at the bottom of the stem carry the tension. A T-beam typically has a narrower stem than an ordinary rectangular beam. These stems are typically spaced from4’-0” apart to more than12’-0”. The slab portion above the stem is designed as a one-way slab spanning between stems (see Lecture6).

Greetings my dear brother and I thank you for your invitation to,,, may Carey from my point of view that the comparison between these two elements open to be fair, but to take them in terms , serviceability and economy. Following these aspect a design for both T-Beam and Box Girder has been performed. After calculation two basics material consumption steel and concrete the most economical has been selected. This study is on the basis of moment of resistance of section, shear capacity of section and cost effective solution from both T-Beam and Box Girder Bridge.Bridge is life line of road network, both in urban and rural areas. With rapid technology growth the conventional bridge has been replaced by innovative cost effective structural system. One of these solution present two structural RCC systems that are T-Beam Girder and box Girder Bridge.

Box girders, have gained wide acceptance in freeway and bridge systems due to their structural efficiency, better stability, serviceability, economy of construction and pleasing aesthetics. Box girder design is more complicated as structure is more complex as well as needed sophisticated from work. In the place of Box Girder if we talk about T-Beam Girder geometry is simple and does not have sophisticated in construction.

Bridge design is an important as well as complex approach of structural engineer. As in case of bridge design, span length and live load are always important factor. These factors affect the conceptualization stage of design. The effect of live load for various span are varied. In shorter For25 m span,the design of bridge structure for25 m of span. The most obvious choice of this span is T- Beam and Box Girder. They have their own characteristics and limitations as T-Beam has easy construction mythology, where as Box girder has sophisticated and costly formwork. In present study a two lane simply supported RCC T- Beam Girder and RCC Box Girder Bridge was analyse for dead load and IRC moving load. The dead load calculation has been done manually and for live load linear analysis is done on Staad Pro. T-Beam Girder is more economical but if span is more than25 m, So Box Girder is always suitable.Due to the analysis shows T-Beam Girder has produced less moment than Box Girder units. This means. T-Beam Girder has less heavier section than two cell box Girder .This type of Bridge lies in the high torsional rigidity available because of closed box section.The analysis shows T-Beam Girder has produced less shear than Box Girder units because of cross section area of concrete..But the bending moment on T-Beam Girder for standard arrangements of beams formed more.Live load shear forces for Box Girder are less after applying distribution factor due to its symmetry.T-Beam girder are more resistance capacity of moment and shear for25 m span. Considering same shear reinforcement in both T-Beam Girder and Box Girder. T-Beam capacities to resist the shear are more. the quantity of concrete is almost same but the quantity of steel has more in Box Girder Bridge.The following conclusion are drawn upon -

1. Service Dead load bending moments and Shear force for T-beam girder are lesser than two cell Box Girder Bridge. Which allow designer to have lesser heavier section for T-Beam Girder than Box Girder for25 m span.

2. Moment of resistance of steel for both has been evaluated and conclusions drawn that T-Beam Girder has more capacity for25 m span.

3. Shear force resistance of T-Beam Girder is more compared to two cell Box Girder for25 m span.

4. Cost of concrete for T-Beam Girder is less than two cell Box Girder as quantity required by T-beam Girder.

5. Quantity of steel for T-beam Girder is less so cost of steel in T-Beam is less as compared to two cells Box Girder Bridge.

Thanks. I Agree with Omair and Fouad.

Box girder

Pedestrian bridges executed with a T-girder construction allow longer spans and offer low maintenance costs. The T-girder cross section is built up by transversely joining several vertical girder webs and horizontal glulam beams. The girders are held together with glue and transverse bracing.

Thanks for all the colleagues.....

Span range is more for box bridge girder as compare to T-beam Girder Bridge resulting in comparatively lesser number of piers for the same valley width and hence results in economy.

A box girder is formed when two web plates are joined by a common flange at both the top and the bottom. The closed cell which is formed has a much greater torsional stiffness and strength than an open section and it is this feature which is the usual reason for choosing a box girder configuration.

Box girders are rarely used in buildings (box columns are sometimes used but these are axially loaded rather than in loaded in bending). They may be used in special circumstances, such as when loads are carried eccentrically to the beam axis

“When tension flanges of longitudinal girders are connected together, the resulting structure is called a box girder bridge”.

Box girders can be universally applied from the point of view of load carrying, to their indifference as to whether the bending moments are positive or negative and to their torsional stiffness; from the point of view of economy. Box girder bridges have a number of key advantages when compared to the T- beam girders. Box girders offer better resistance to torsion. This is beneficial especially for a curved bridge. Larger girders and stronger flanges can be used as this allows for a longer span between the support posts that hold the bridge. The huge hollow boxes can be used to place the Water lines, telephone cables and other utility lines.

Thank you Mr.Jaafer

Agree with Mr. Basit Ali