Register now or log in to join your professional community.

Typre of concrete pile pretty much depend on the construction method such as 1) driven piles are prefabricated and they are driven into the ground using pile hammer.

2) Cast in situ piles which are constructed mostly on the site. holes are drilled into the ground to specific dimensions then reinforcement put into place before filling the hole with concrete

3) Driven and cast in situ piles which is a special type of a method combining both of the above methods for in stance an a pre made steel shell is driven into the ground then concrete is poured into the shell

Piles can by classified on the basis of following characteristics:

Types of piles based on the mechanism of Load Transfer:

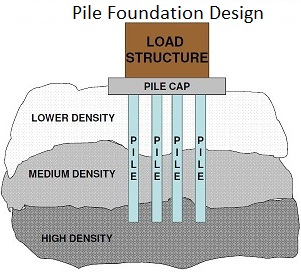

If a bedrock or rocklike material is present at a site within a reasonable depth, piles can be extended to the rock surface. In this case, the ultimate bearing capacity of the pile depends entirely on the underlying material; thus the piles are called end or point bearing piles. In most of these cases the necessary length of the pile can be fairly well established.

Instead of bedrock, if a fairly compact and hard stratum of soil is encountered at a reasonable depth, piles can be extended a few meters into the hard stratum.

Instead of bedrock, if a fairly compact and hard stratum of soil is encountered at a reasonable depth, piles can be extended a few meters into the hard stratum.

In these types of piles, the load on pile is resisted mainly by skin/friction resistance along the side of the pile (pile shaft). Pure friction piles tend to be quite long, since the load-carrying. Capacity is a function of the shaft area in contact with the soil. In cohesion less soils, such as sands of medium to low density, friction piles are often used to increase the density and thus the shear strength. When no layer of rock or rocklike material is present at a reasonable depth at a site, point/end bearing piles become very long and uneconomical. For this type of subsoil condition, piles ate driven through the softer material to specified depth.

In the majority of cases, however, the load-carrying capacity is dependent on both end-bearing and shaft friction.

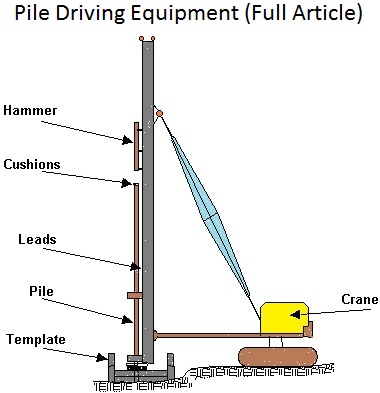

Classification of Piles according to the Method of Installation of piles They are usually pre-formed before being driven, jacked, screwed or hammered into ground. This category consists of driven piles of steel or precast concrete and piles formed by driving tubes or shells which are fitted with a driving shoe. The tubes or shells which are filled with concrete after driving. Also included in this category are piles formed by placing concrete as the driven piles are withdrawn.

They are usually pre-formed before being driven, jacked, screwed or hammered into ground. This category consists of driven piles of steel or precast concrete and piles formed by driving tubes or shells which are fitted with a driving shoe. The tubes or shells which are filled with concrete after driving. Also included in this category are piles formed by placing concrete as the driven piles are withdrawn.

(Also See: ![]() Types of Soil Settlement )

Types of Soil Settlement )

They require a hole to be first bored into which the pile is then formed usually of reinforced concrete. The shaft (bore) may be eased or uncased depending upon type of soil.

Types of Piles based on MaterialsDifficult to splice, vulnerable to damage in hard driving, vulnerable to decay unless treated with preservatives (If timber is below permanent Water table it will apparently last forever), if subjected to alternate wetting & drying, the useful life will be short, partly embedded piles or piles above Water table are susceptible to damage from wood borers and other insects unless treated.

Comparatively low initial cost, permanently submerged piles are resistant to decay, easy to handle, best suited for friction piles in granular material.

Easy to splice, high capacity, small displacement, able to penetrate through light obstructions, best suited for end bearing on rock, reduce allowable capacity for corrosive locations or provide corrosion protection.

In general, a composite pile is made up of two or more sections of different materials or different pile types. The upper portion could be eased cast-in-place concrete combined with a lower portion of timber, steel H or concrete filled steel pipe pile. These piles have limited application and arc employed under special conditions.

two types

wet boring

dry boring