Inscrivez-vous ou connectez-vous pour rejoindre votre communauté professionnelle.

Any team activity will increase the team spirit which a major factor in increased productivity and performance.

Dear Faris,

Answer is hidden in the question. Risks are depend on the type of organization. So I can give some samples:

a) Warehouse operation oriented SCM entity:

a-1) Absence of parts/goods

a-2) Data failure in system (ERP or similar softwares)

a-3) Lack of education, individual failures

We need all statistics about failures and we need to know repetative failues.

b) Transport oriented entities:

b-1) Failure of Optimization in routes

b-2) Lack of understanding "Milk-Run" opportunity

b-3) Foriegn competitors, custom risks

c) Automotive like entities:

c-1) Supplier risks (Alternative needs, quality risks, negotiation failures)

c-2) Lack of lean understanding

Managing supply-chain risk is difficult because individual risks are often interconnected. As a result, actions that mitigate one risk can end up exacerbating another. Consider a lean supply chain. While bare-bones inventory levels decrease the impact of over-forecasting demand, they simultaneously increase the impact of a supply chain disruption. Similarly, actions taken by any company in the supply-chain can increase risk for any other participating company.

Supply-chain risks can become full-fledged supply-chain problems, causing unanticipated changes in flow due to disruptions or delays. Disruptions can be frequent or infrequent; short- or long-term; and cause problems for the affected organization(s), ranging from minor to serious. A simple delay along the chain may create a temporary risk, whereas a sole supplier holding up a manufacturer to force a price increase represents a long-term risk. A machine breakdown may have a relatively minor impact on a manufacturing company with redundant capacity, whereas a war that disrupts shipping lanes can have a major impact on a shipping company.

Most companies develop plans to protect against recurrent, low-impact risks in their supply chains. Many, however, all but ignore high-impact, low-likelihood risks. For instance, a supplier with quality problems represents a common, recurrent disruption. Without much effort, the customer can demand improvement or find a substitute. In contrast, in regions where earthquakes are rare, preparedness to prevent major disruption may be weak or uneven.

Leading companies deal with this range of supply-chain risks by holding reserves. Just as insurance companies hold cash reserves to meet claims, top manufacturers hold supply-chain reserves that include excess inventory, excess capacity and redundant suppliers. The big challenge for managers here: Mitigate risk by intelligently positioning and sizing supply-chain reserves without decreasing profits. So while stockpiling inventory may shield a company against delivery delays by suppliers, building reserves in an undisciplined fashion also drives up costs and hurts the bottom line. The managers’ role here is akin to that of a stock portfolio manager: Attain the highest achievable profits (reward) for varying levels of supply-chain risk and do so efficiently. (See “Choosing Supply-Chain Risk/Reward Trade-Offs.”) This means the manager must seek additional profits for any level of risk protection and preparedness or increase prevention and preparedness without reducing profits. Success at this task requires a good understanding of supply-chain risks and remedies, both broad and tailored to the manager’s own company.

Choosing Supply-chain Risk/reward Trade-offs View Exhibit

View Exhibit

Delays in material flows often occur when a supplier, through high utilization or another cause of inflexibility, cannot respond to changes in demand. Other culprits include poor-quality output at supplier plants (or at their suppliers’ plants), high levels of handling or inspections during border crossings and changing transportation modes during shipping. If material-flow delays are frequent, however, companies can plan mitigation strategies based on historical information.

Organizations can avoid delays, or at least prepare for them, by appropriately and economically placing and sizing their capacity and inventory reserves. One simple solution is to maintain excess flexible capacity in existing plants. Toyota Motor Corp., for example, accomplishes this on its assembly lines by employing team leaders who can work on any station. Besides reducing the need for extra, station-specific workers to cover absences, the strategy also ensures that daily production goals are met, even when minor assembly-line problems occur.3

Another solution for delays is balancing capacity and inventory, depending on the cost of the products. For example, telecommunications equipment maker Cisco Systems Inc. has capacity to assemble higher-value items in the United States. This enables the company to respond quickly to orders from up-market domestic customers. In contrast, Cisco holds an inventory of lower-value, high-demand items produced in low-cost (but not very responsive) locations overseas. Thus, by matching approach to product value, Cisco reduces both supplier-delay risks and inventory costs.

Yet another solution is to combine inventory with different transport modes. Dell Inc. holds very little inventory of high-value components in the United States. Instead, the personal computer manufacturer uses high-cost air transportation to deliver components from the Far East as needed. For less expensive components, however, Dell keeps some inventory that is shipped regularly at low cost to the United States. In this way Dell, minimizes delay-related risk as well as inventory-related costs.

Disruptions to material flows anywhere in the supply chain are unpredictable and rare but often quite damaging. Examples abound of how natural disasters, labor strikes, fires and terrorism have halted the flow of materials. For instance, following a February 1997 fire at a parts factory owned by Japanese manufacturer Aisin Seiki Co. Ltd., a key supplier for Toyota, the auto giant was forced to temporarily shut down production at most of its Japanese plants.4 The negative impact can be international: The 1994 Kobe earthquake in Japan, to cite just one case, left California-based sound card maker Kelly Micro Systems and many other small companies without any supply of parts.5 The California dockworkers strike in 2002 produced shortages of high-demand retail items.6 The 2001 bankruptcy of U.K.-based UPF-Thompson, sole chassis supplier to Ford Motor Co.’s Land Rover unit, caused major problems for the automaker.7 Immediately after the attacks of September 11, 2001, U.S. auto manufacturers ran short of parts because transport trucks had been delayed at the Canadian border.8 In addition, supply disruptions also can increase prices, as the Midwest discovered painfully in August 2001, when regional gasoline prices skyrocketed following a refinery fire at the height of summer demand.9

Companies can counter disruptions in material flow by building inventory, or by having redundant suppliers (since it is unlikely that all suppliers would be disrupted simultaneously). However, holding inventory in this situation can get very costly. The reason is simple:While holding costs are incurred continually, the inventory would be used only in the rare event of a disruption. In essence, the company pays (and continues to pay) for reserves that may never be tapped. Still, building inventory does make sense if the disruption can be predicted with reasonable confidence. In 2002, for example, many retailers selectively built up inventories after learning of the impending California dockworker’s strike. As a result, when supply was disrupted, as predicted, damage was minimal. Stockpiling inventory as a hedge against disruption also makes sense for commodity products with low holding costs and no danger of obsolescence. The large petroleum reserve kept by the United States is a perfect example of this strategy.

For products with high holding costs and/or a high rate of obsolescence, using redundant suppliers is a better strategy. Motorola Inc., for example, buys many of its handset components from multiple vendors. Doing so prepares the company for disruptions without building up fast-depreciating inventory. Motorola lowers the cost of redundancy by using multiple suppliers for high-volume products and single sourcing for low-volume products. This approach helps the company lower the risk of disruption while preserving economies of scale at its suppliers.

Systems RiskThe more a company networks its information systems, the greater the threat that a failure anywhere can cause failure everywhere. Although rare, a breakdown of information infrastructure can devastate today’s highly networked environments. Case in point: the “Love Bug” computer virus. In 2002, the fast-spreading infection shut down e-mail at the Pentagon, NASA and Ford, among others, causing billions of dollars in estimated damages.10

The banking industry has long recognized systems risk as a major threat. In 1988, the Basel Committee on Banking Supervision warned about the growing reliance on globally integrated systems. “The greater use of more highly automated technology has the potential to transform risks from manual processing errors to system failure risks,” the committee wrote.11

The best defense against systems failure? Robust backup systems and well-designed, well-communicated recovery processes that duplicate all data and transactions. Such approaches helped securities firms recover quickly and convincingly following the World Trade Center attacks in 2001.12

Forecast RiskForecast risk results from a mismatch between a company’s projections and actual demand. If forecasts are too low, products might not be available to sell. Forecasts that are too high result in excess inventories and, inevitably, price mark-downs. Long lead times, seasonal demand, high product variety and smaller product life cycles all increase forecast error. Errors tend to be greater when a few customers make larger purchases (as opposed to many customers making smaller purchases).

Forecast inaccuracies can also result from information distortion within the supply chain. In late 2003, for example, product shortages in Western Europe led Nokia customers to order more than they needed so they would be able to meet demand if Nokia began rationing or allocations. Unfortunately, the exaggerated figures distorted Nokia’s reading of the market, causing the company to inaccurately forecast sales.13

Other causes of information distortion include promotions and incentives that lead to forward buying; batching of purchases, which leads to higher volatility in orders; and lack of knowledge of end-customer demand at upstream locations. Distortion increases in the supply chain as you get farther away from the end consumer, a phenomenon known as the bullwhip effect.14

Companies can reduce the sting of the bullwhip effect, though, by adjusting pricing and incentives to decrease variation in orders. Increasing the visibility of demand information across the supply chain also helps. Continuous replenishment programs (CRP), and collaborative planning, forecasting and replenishment (CPFR), and other supply-chain initiatives also can soften the bullwhip effect.

Here again, forecast risk can be lessened by selectively holding inventory and/or building responsive production and delivery capacity. Holding inventory is appropriate for commodity products with relatively low holding costs; responsive delivery is better for expensive products with short life cycles (and corresponding large forecast errors). Motorola practices responsive delivery each day when it flies in phones from China in response to demand by customer Nextel Communications Inc. Instead of stocking parts for uncertain demand, Dell also flies in high-value items from Asian suppliers on an as-needed basis.

Intellectual Property RiskIntellectual property risk has grown rapidly as supply chains become less vertically integrated and more global, and as companies outsource to the same manufacturers used by competitors. Because profitability — and often business models as well — depend on keeping a competitive edge, intellectual property risk has dramatic, long-term implications.

Companies can mitigate intellectual property risk by bringing, or keeping, some production in-house, or at least under direct company control. That is a major reason why Motorola owns some of the testing equipment at supplier locations. Managers also can decrease risk by limiting the flow of new intellectual property into countries with weak legal protections.

Companies like Cisco, which outsources all manufacturing, also lower risk by creating business processes that cannot be easily replicated by a single manufacturer. Electronics manufacturer Sharp Corp. even repairs equipment itself, thus preventing any possibility, accidental or otherwise, that its vendors will share proprietary information with Sharp’s competitors. The company goes so far as to reprogram various computer-aided machines used by its vendors without sharing the information.

Procurement RiskProcurement risk refers to unanticipated increases in acquisition costs resulting from fluctuating exchange rates or supplier price hikes. For example, the recent weakening of the U.S. dollar drove up costs for U.S. companies sourcing in Europe. The devaluation also created the risk of a dollar collapse, the result of Asian economies propping up the currency to maintain exports to the United States. Interestingly, hedging against the dollar’s fall also has led to higher oil prices, creating problems for petrochemical and energy-intensive industries. Needless to say, price increases are more likely when a company uses only one supply source. Fortunately, managers have several sharp tools at their disposal for minimizing price increases.

Exchange-rate risk can be countered by creating financial hedges, balancing cost and revenue flows by region and building flexible global capacity. Toyota’s manufacturing strategy, to cite one example, allows each plant to serve the local market and at least one other market across the world. This lets Toyota shift production if exchange rates change appreciably.

Price increases by suppliers can be blunted in several ways: by signing long-term contracts, having redundant suppliers or, in rare instances, holding inventory. But be warned that long-term purchasing can badly damage profits if prices for the contracted goods fall. For example, obligations signed by California during the peak of its electricity crisis in 2001 forced the state to pay 800% more than the 2002 market price.15

Contracting with redundant suppliers can work, but only if companies can maintain economies of scale. Global giants like Toyota seek out local economies of scale by single-sourcing at the plant level, but enlisting redundant suppliers globally. So even though a company might be the sole supplier to a Toyota plant, it must keep prices down to compete for business across the entire Toyota network. Alternatively, some firms use multiple, redundant suppliers, even if it means sacrificing some economies of scale. Cisco, for one, claims to have four or five more suppliers than it needs. The company keeps the resulting higher costs in check by monitoring and benchmarking suppliers against each other.16 A good example of using inventory to counter the threat of price increases is the U.S. strategic oil reserve policy. Meant primarily to prevent oil supply disruption, the reserve also has been used on occasion to keep prices down. In another instance, the International Paper Co. keeps prices of raw materials down by sourcing them from independent forest owners, as well as from its own forests.

Receivables RiskReceivables risk, the possibility of being unable to collect on receivables, can torpedo the performance of any company. In 2002, Sears Roebuck’s credit division reported unexpected losses caused by delinquent cardholders.17 As a result, Sears stock plummeted more than 30% in one day. The company learned the hard way that filtering customers for creditworthiness is a very prudent and powerful way to reduce receivables risk.

Another approach is to spread the risk across more customers. Elmhurst, Illinois-based McMaster-Carr Supply Co., a maintenance-materials supplier with hundreds of thousands of customers, enjoys a much lower receivables risk than a competitor selling to a single, large customer. The Achilles heel here is a widespread economic shock that harms the creditworthiness of all customers, a fate that befell Cisco during the dot-com bust.

Inventory RiskExcess inventory hurts financial performance. That was the case in late 2000, when the personal computer industry carried roughly 12 weeks of inventory. The killer combination of excess inventory and falling prices hurt many companies, notably Compaq Computer Corp. Inventory risk hinges on three factors: the value of the product, its rate of obsolescence and uncertainty of demand and supply. As we have seen, holding excess inventory for products with high value or short life cycles can get expensive. The strategy can work quite well, however, for low-value commodity products that have low obsolescence rates. To complicate matters even further, inventory risk also increases as product variety grows.

Three time-tested approaches can help managers mitigate inventory risk: (1) pooling inventory, (2) creating common components across products and (3) postponing or delaying the last stage of production until all orders are in hand. Online bookseller Amazon.com serves all its customers in the United States with inventory housed in a handful of warehouses. Book retailer Borders Books & Music supplies its customers with inventory in several hundred stores. Each Amazon warehouse pools demand over a large geographical area, leading to more stable forecasts and lower total inventory. The strategy helps Amazon achieve 14 inventory turns per year, compared with two for Borders.

The paint industry illustrates well how to leverage component commonality and “postponement” of variety. Traditionally, manufacturers held paint inventory in a rainbow of different colors. Today, paint inventory is held as a common base, which is then mixed to exact color specifications after the customer orders. This simple but powerful change has significantly lowered paint inventory at retail stores. Apparel maker Benetton Group SpA also practices pooling and postponement. An inventory of undyed sweaters gets stockpiled in one location; coloring takes place only after specific orders have been received. This pooling of demand across geographical areas, and across colors, helps Benetton greatly reduce inventory risk while more effectively meeting customer demand.18

Companies can also minimize inventory risk by working with a highly responsive supplier, especially for high-value, short life-cycle products. Excess capacity can also lower the amount of inventory required. For example, by running plants at 80% utilization, Toyota can handle demand variation without having to hold inventory.

Capacity RiskUnlike inventory, capacity can only be increased or decreased over a period of time. Thus, building excess capacity usually becomes a strategic choice. Excess (and thus, underutilized) capacity hurts financial performance. That was the case in 2002–2003, when many semiconductor firms had to operate at about 50% capacity because of soft demand.

Managers can lower excess capacity risks by making existing capacity more flexible. Flexibility is a form of pooling that allows use of the same capacity for a variety of products. For example, plants owned by Japanese truck manufacturer Hino Motors Ltd. employ multiple assembly lines on which the number of workers determines line speed. This flexibility lets Hino change production on any line by moving workers (capacity) to meet fluctuating demand. It also greatly reduces the excess capacity of workers Hino would have to carry if each worked only on a specific line.

Toyota decreases risks from idle capacity by ensuring that each plant is flexible enough to supply more than one market. Demand fluctuations can be satisfied from a variety of plants, which decreases the total capacity required. As noted, Toyota carries the idea of flexibility down to the shop floor, where team leaders can work on any station in the assembly line, reducing the need for spare station-specific workers to cover absences.19

Lastly, a company can minimize excess capacity by serving geographically scattered customers from the same location. Italian automaker Ferrari SpA, for example, minimizes total production capacity by centralizing all car production in a single plant. The arrangement also gives Ferrari economies of scale, even though the company procures and produces much less than the big auto companies.

With so many related risks and risk-mitigation approaches to consider, managers must do two things when they begin to construct a supply-chain risk management strategy. First, they must create a shared, organizationwide understanding of supply-chain risk. Then they must determine how to adapt general risk-mitigation approaches to the circumstances of their particular company. Managers can achieve the former through stress testing and the latter through tailoring.

Stress testing is a group exercise that helps managers and their companies understand and prioritize supply-chain risks. “What if ” scenarios help key players focus on the supply chain one link at a time. This strategy offers an especially effective way to gain buy-in and shared ownership in project teams tackling supply-chain risk.

The first step in stress testing is to identify key suppliers, customers, plant capacity, distribution centers and shipping lanes. Next, the team surveys locations and amounts of inventory represented by components, work-in-process and finished goods. Managers then probe each potential source of risk, which helps assess possible supply-chain impacts as well as the company’s level of pre-paredness. Facilitators ask questions such as, “What might happen if a particular supplier could not deliver for a month?” or “What if a supplier raised prices by 20% at the termination of a contract?” Questions pertaining to key customers might include: “What if demand went up or down by 20%?” or “What if a customer delayed cash payment by a month?” (See “Stress Testing Your Supply Chain.”) When considering questions during stress testing, managers should realize that figures such as “20%”or “one month” are not sacred, but simply represent numbers large enough to be significant and small enough to be realistic.

Stress Testing Your Supply Chain View Exhibit

View Exhibit

It is wise to position stress testing as a “thought experiment” to help the company prepare for unforeseen events, rather than focusing on the debatable likelihood of such events. Similarly, it is useful to frequently remind people of the goal: preparing the supply chain for unforeseen events and greatly lowering risk, both at the lowest possible cost.

Through stress testing, managers should be able to identify risk-mitigation priorities for the near, medium and long term. They will have identified product families at risk, as well as individual plants, shipping lanes, suppliers or customers that could pose risks. Managers will also have a clear idea of what risks might have an impact on sales, procurement costs, revenues, prices or even reputation.

Leading companies mitigate risk by building various forms of reserves, including inventory, capacity, redundant suppliers and responsiveness. Managers must keep a vigilant eye on the trade-off between the risk and the cost of building a reserve to mitigate it.20 Three key relationships influence this optimal balance. (See “Balancing Supply-Chain Risk/Reward Relationships.”)

Balancing Supply-chain Risk/reward Relationships View Exhibit

View Exhibit

The first relationship is the increasing cost of risk reduction. This simply means that using inventory to cover a high level of demand risk costs much more than covering a low level of risk. The second relationship shows that pooling forecast risk, receivables risk or some other risk reduces the amount of reserve required for a given level of risk coverage. Thus, the required level of inventory needed to mitigate forecast risk decreases as it is pooled. The third relationship shows how the benefit of pooling grows with the level of risk covered: The benefit of pooling inventory is great only if the product has high forecast or inventory risk.

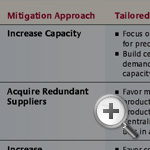

Managers can balance these relationships to tailor their response to risk with a surer grasp of extent and cost of reserve. The following rules of thumb can be applied to tailor risk-mitigation strategies: When the cost of building a reserve is low, reserves should be decentralized. When the cost is high, reserves should be pooled. If the level of risk is low, focus on reducing costs. If the risk is high, focus on risk mitigation. (See “Rules of Thumb for Tailored Risk Management.”) By tailoring reserves for all risk-mitigation strategies, companies can maximize rewards for the same level of risk, or lower risks for the same reward. (See “Tailoring Reserves for Risk Mitigation.”)

Rules Of Thumb For Tailored Risk Management View Exhibit

Tailoring Reserves For Risk Mitigation

View Exhibit

Tailoring Reserves For Risk Mitigation

View Exhibit

View Exhibit

Beyond reserve costs, companies must also consider product volumes. Fast-moving standard items, with low margins and low forecast risk, call for different reserves than slow-moving special products with high margins and greater forecast risk. When planning capacity, managers should select an efficient, low-cost supplier for fast-moving (low-risk) items. In contrast, a more responsive supplier better suits slow-moving (high-risk and high-value) items. For example, Cisco tailors its response by manufacturing fast-moving products in specialized, inexpensive but not-so-responsive Chinese plants. High-value, slow-moving items are assembled in responsive, flexible (and more expensive) U.S. plants. Sony Corp. also exploits this strategy, utilizing flexible but high-cost plants in Japan and low-cost but specialized plants in Malaysia and China.

As much as possible, a specialized, decentralized approach offers the best way to keep capacity for fast-moving, commodity items with low forecast risk. Doing so should produce greater responsiveness and lower transportation costs — but only if doing so maintains adequate economies of scale. In contrast, capacity for slow-moving, short life-cycle products with high forecast risk should be made more flexible and centralized to pool demand. This helps explain why automakers, for example, often build specialized plants for fast-moving products in each major market, but centralize the flexible production of high-end, slower-selling models.

When capacity is expensive, managers can reduce supply-chain costs by centralizing capacity to pool risk. As costs decline, capacity must be decentralized further. Consider the personal computer industry. PCs can be assembled to order in two different ways. In one, the Dell model, capacity is centralized. In the other model, widely used in India, several companies sell component kits to local assemblers for assembly on demand. Given the low cost of assembly capacity in India, it is economical to decentralize capacity, even though this action reduces pooling and increases the overall size of assembly capacity across the supply chain. In contrast, given the higher cost of capacity in the United States, centralizing buffer capacity is more effective.

In addition to separating products with different risk characteristics, managers must also consider separating capacity for the low-risk and high-risk aspects of each product. Utility companies use this strategy by employing low-cost, coal-fired power plants to handle predictable base demand, and utilizing responsive but high-cost gas- and oil-fired power plants to handle uncertain peak demand. Similarly, Benetton produces the predictable base load of its knit garments using a cheaper process that starts with dyed thread and only produces the uncertain portion using the more expensive process of dyeing knit garments.21

By continually stress testing their supply chains and tailoring reserves, managers can protect and improve the bottom line in the face of many types of supply-chain risks. Like Ericsson, smart companies do not wait for lightning to strike twice before taking action.

In such crises some corrective and preventive actions to be taken but not limited to the listed below:-These actions include engaging in significant cost reduction (including overhead costs), introducing zero-based budgets, establishing war rooms, and redefining footprints and networks. However, it is also crucial to understand the trade-offs between myopic and sustainable actions. In addition, it is key to plan for the inevitable and prepare the supply chain to deal with tough times. 1-supply chain managers should gain a clear understanding of potential demand scenarios, as demand should be the basis of all supply chain planning. 2-firms should safeguard their supplies to avoid any critical bottlenecks as suppliers go out of business. 3-firms must accelerate all efforts to create flexible and breathing supply chains that can cope with all types of variability. 4-managers should carefully reduce inventories to free up cash that is essential for turnaround actions. 5-firms should also consider the light at the end of the tunnel and should begin to position themselves for the inevitable upswing.

Hello Team,

Companies/Client have always been challenged to adapt their supply chains to their success in the market.

During boom periods, firms are eager to avoid costly backlogs, to align manufacturing capacities with growing demand, and to ensure raw materials from new suppliers.

Meanwhile, supply chains are accelerated, costly air freight is accepted, and large batches are produced because goods will be sold at some stage. In contrast, during difficult times, firms must address shrinking customer orders, face increasing competition, and see decreasing margins.

Accordingly, priorities for supply chains differ significantly. Firms must focus on cutting costs, reducing capacities, consolidating suppliers, and freeing up cash by taking out inventory.

Difficult times frequently relate to an individual firm’s situation: These could include poor top management decisions, cost pressures from a new competitor, or demand being hit by poor customer service. However, difficult times are also frequently caused by changing economic climates.

During the Financial Crisis that started five years ago, an unforeseen contraction in demand across numerous industries challenged supply chains globally beyond anything observed in the past. As the economy continued to drift downward, a significant turning point occurred on September 15, 2008, when Lehman Brothers, the fourth largest U.S. investment bank at that time, declared bankruptcy. The collapse of Lehman Brothers sent a shockwave through the financial world and triggered an unprecedented decline in the global economy.

Regards,

Saiyid

I fully agree with the answers been added by EXPERTS........Thanks.

Thank you for invitation. I agree with the answer of Mr. GOKHAN TASDEVIREN

GOKHAN TASDEVIREN Deputy General Manager- Technical atTEKNOTRANS ENGINEERING COMPANY

Follow

Deputy General Manager- Technical. Its simple and clear.

Market consolidation

Instability is the norm

Regulations are a factor

A higher profile for risk management

I agree with Mr Vinod Jetley his answer full>

thank you for ur invite but i didn't expert on this filed

considering all risks at the beginning and analyzing them and predict the best response to those risk could be a good idea but still having a watch dog in the process to alarm as soon as any problem happen to react in time is necessary, specially in some projects which we have to pay more for our logistics and they are costly because of the project situation.