Register now or log in to join your professional community.

Curing plays an important role on strength development and durability of concrete. Curing takes place immediately after concrete placing and finishing, and involves maintenance of desired moisture and temperature conditions, both at depth and near the surface, for extended periods of time. Properly cured concrete has an adequate amount of moisture for continued hydration and development of strength, volume stability, resistance to freezing and thawing, and abrasion and scaling resistance. The length of adequate curing time is dependent on the following factors:

Slabs on ground (e.g. pavements, sidewalks, parking lots, driveways, floors, canal linings) and structural concrete (e.g. bridge decks, piers, columns, beams, slabs, small footings, cast-in-place walls, retaining walls) require a minimum curing period of seven days for ambient temperatures above 40 degrees Fahrenheit1.American Concrete Institute (ACI) Committee 301 recommends a minimum curing period corresponding to concrete attaining 70 percent of the specified compressive strength2. The often specified seven-day curing commonly corresponds to approximately 70 percent of the specified compressive strengths. The 70 percent strength level can be reached sooner when concrete cures at higher temperatures or when certain cement/admixture combinations are used. Similarly, longer time may be needed for different material combinations and/or lower curing temperatures. For this reason, ACI Committee 308 recommends the following minimum curing periods3:

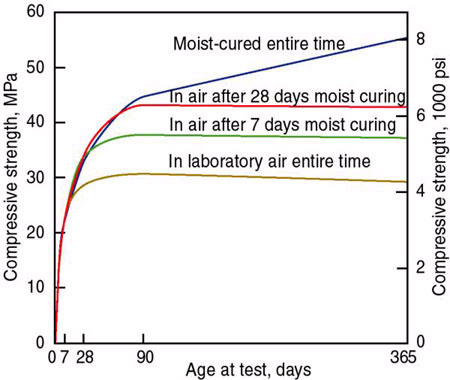

Effect of curing duration on compressive strength development is presented in Figure 1.

Figure 1. Moist Curing Time and Compressive Strength Gain

Figure 1. Moist Curing Time and Compressive Strength Gain

Higher curing temperatures promote an early strength gain in concrete but may decrease its 28-day strength. Effect of curing temperature on compressive strength development is presented in Figure 2.

Figure 2. Effect of Curing Temperature on Compressive Strength

There are three main functions of curing: 1) Maintaining mixing water in concrete during the early hardening process

Ponding and immersion Ponding is typically used to cure flat surfaces on smaller jobs. Care should be taken to maintain curing water temperature at not more than 20 degrees Fahrenheit cooler than the concrete to prevent cracking due to thermal stresses. Immersion is mainly used in the laboratory for curing concrete test specimens.Spraying and fogging Spraying and fogging are used when the ambient temperatures are well above freezing and the humidity is low. Fogging can minimize plastic shrinkage cracking until the concrete attains final set.Saturated wet coverings Wet coverings saturated with water should be used after concrete has hardened enough to prevent surface damage. They should be kept constantly wet. Left in Place Forms Left in place forms usually provide satisfactory protection against moisture loss for formed concrete surfaces. The forms are usually left in place as long as the construction schedule allows. If the forms are made of wood, they should be kept moist, especially during hot, dry weather.

2) Reducing the loss of mixing water from the surface of the concrete

Covering concrete with impervious paper or plastic sheets Impervious paper and plastic sheets can be applied on thoroughly wetted concrete. The concrete surface should be hard enough to prevent surface damage from placement activities. Applying membrane-forming curing compounds Membrane-forming curing compounds are used to retard or reduce evaporation of moisture from concrete. They can be clear or translucent and white pigmented. White-pigmented compounds are recommended for hot and sunny weather conditions to reflect solar radiation. Curing compounds should be applied immediately after final finishing. Curing compound shall comply with ASTM C3094 or ASTM C13155.

3) Accelerating strength gain using heat and additional moisture

Live steam Live steam at atmospheric pressure and high-pressure steam in autoclaves are the two methods of steam curing. Steam temperature for live steam at atmospheric pressure should be kept at about 140 degrees Fahrenheit or less until the desired concrete strength is achieved.Heating coils Heating coils are usually used as embedded elements near the surface of concrete elements. Their purpose is to protect concrete from freezing during cold weather concreting. Electrical heated forms or pads Electrical heated forms or pads are primarily used by precast concrete producers.Concrete blankets Concrete insulation blankets are used to cover and insulate concrete surfaces subjected to freezing temperatures during the curing period. The concrete should be hard enough to prevent surface damage when covering with concrete blankets.

Other forms of curing include internal moist curing with lightweight aggregates or absorbent polymer particles. For mass concrete elements (usually thicker than 3 feet), a thermal control plan is usually developed to help control thermal stresses. Additional information can be found in ACI Committee 308 report Guide to Curing Concrete. For specialty concretes, it is recommended to refer to other ACI reports as follows:

Curing in either cold or hot weather requires additional attention. In cold weather, some of the procedures include heated enclosures, evaporation reducers, curing compounds, and insulating blankets. The temperature of fresh concrete shall be above 50 degrees Fahrenheit. The curing period for cold weather concrete is longer than the standard period due to reduced rate of strength gain. Compressive strength of concrete cured and maintained at 50 degrees Fahrenheit is expected to gain strength half as quickly as concrete cured at 73 degrees Fahrenheit. In hot weather, curing and protection are critical due to rapid moisture loss from fresh concrete. The curing actually starts before concrete is placed by wetting substrate surfaces with water. Sunscreens, windscreens, fogging, and evaporation retardants can be used for hot weather concrete placements. Since concrete strength gain in hot weather is faster, curing period may be reduced. Additional information can be found in ACI 306.1, Standard Specification for Cold Weather Concreting, ACI 306R, Cold Weather Concreting, ACI 305.1, Specification for Hot Weather Concreting, and ACI 305R

To develop strength and durability.

to retain the water in concrete mix, which is essential for cement hydration